With the continuous development of the packaging industry, people's demand for packaging boxes is getting higher and higher. The quality of printed products directly affects the customer's experience. So what printing processes are used when China printers for book and box printing?

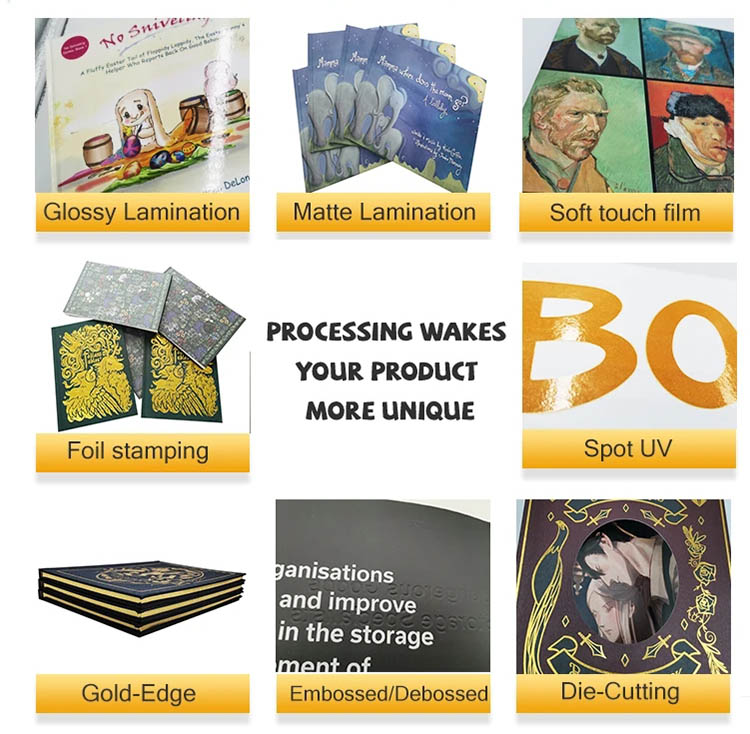

In the packaging and printing industry, our common post-processing processes such as lamination, spot UV, hot stamping, embossing, etc make box packaging more refined and beautiful. Next, letŌĆÖs learn more about these printing processes.

1. Lamination

Lamination is a popular post-press finish option. It provides both protection and enhancement to printed materials. In the laminating process, the plastic film coated with adhesive and the paper-based printed matter are heated, pressed, cooled, etc., so that the surface of the printed matter is covered with a layer of transparent film. It creates a protective barrier against moisture, smudges, and other external elements. Lamination is available in various finishes, including glossy and matte.

Glossy Lamination

Glossy lamination is a high-shine finish that adds vibrancy and depth to printed materials. It enhances colors and contrasts, making them appear more vibrant and rich. Glossy lamination is commonly used for marketing materials, such as gift box, brochures, business cards, and catalogs. As it gives them a professional and polished look. The glossy finish also makes the printed matter more durable, extending its lifespan.

Matte Lamination

Matte lamination, on the other hand, offers a more subdued and elegant look. It has a frosted, non-reflective surface that reduces glare and fingerprints. It is ideal for materials that will be frequently handled, such as book covers or menus. Matte lamination gives printed materials a sophisticated and professional appearance, without the glossy sheen, more eye-protection.

Glossy lamination with smooth and brightness surface, often used for product types of printed product. While matte lamination due to non-reflective surface and elegant, often used for brand type of package product. Lamination usually apply on 200gsm or more thicker paper.

2. Foil Stamping

Foil stamping is a popular embellishment technique that adds a touch of luxury and elegance to printed materials. It involves applying a metallic or pigmented foil onto the surface of the paper using heat and pressure. Foil stamping can be used to create eye-catching elements, such as logos, titles, or borders, that stand out from the rest of the design.

Foil stamping comes in a wide range of colors and finishes, including gold, silver, copper, holographic, and so on. It can be combined with other post-press finishes, such as embossing or debossing, to create more intricate and visually appealing designs. Foil stamping is commonly used for books, calendars, cards and packaging materials.

3. Spot UV

Spot UV (Ultra Violet) coating is a technique that adds a glossy and raised effect to specific areas of a printed matter. It involves applying a clear UV coating to a select portion of the design, creating a contrast between the glossy and matte surfaces. Spot UV coating can be used to highlight logos, images, or text, giving them a tactile and visually striking appearance.

Spot UV adds depth and dimension to printed materials, making them more visually appealing and memorable. It is commonly used for business cards, book covers, brochures, and packaging materials. The combination of spot UV with other finishes, such as foil stamping or embossing, can create stunning and unique effects.

4. Varnish

Varnish is a clear liquid coating that is applied to the surface of a printed product to enhance its appearance and protect it from wear and tear. It can be applied in various finishes, including glossy, matte, or satin. Varnish adds a smooth and even layer to the printed materials, enhancing the colors and giving them a polished look.

Varnish can be used to create a variety of effects, such as adding a subtle sheen to a design or creating a tactile texture. It can also be used to protect the printed piece from fading, smudging, or scratching. Varnish is commonly used for book interior, postcards, and packaging materials.

5. Emboss/Deboss

Embossing and debossing are techniques that create a three-dimensional effect on the surface of a printed product. Embossing raises the design elements, while debossing recesses them into the paper. These techniques add texture and depth to the printed materials, making them visually appealing and tactile.

Embossing and debossing can be used to create various effects, such as adding a logo, pattern, or texture to the design. They are commonly used for business cards, book cover, and packaging materials. When combined with other finishes, such as foil stamping or spot UV, embossing and debossing can create stunning and unique designs.

6. Die Cut

Die cutting is a process that involves cutting a printed product into a specific shape or design using a sharp steel blade called a die. It allows for the creation of intricate and custom shapes that can not be achieved with traditional cutting methods. Die cutting can be used to add visual interest and uniqueness to printed materials.

Die cutting is commonly used for business cards, packaging materials, books, and marketing materials. Die cut materials stand out from the crowd and leave a lasting impression on the recipients.

7. Laser Foil Stamping

Laser foil stamping is a cutting-edge technique that combines laser technology with foil stamping. It allows for precise and intricate designs to be transferred onto the surface of the printed product using a laser beam. Laser foil stamping can create stunning metallic effects, patterns, or textures. Adding a touch of luxury and sophistication to printed materials. From different angles, it feels like golden light is shining.

Laser foil stamping is often used for high-end products, packaging materials, and marketing materials. It offers endless design possibilities and can be combined with other post-press finishes. Such as embossing or spot UV, to create visually striking and unique effects.

8. Glitter Edge

Glitter edge is a finishing technique that adds a touch of sparkle and glamour to the edges of a printed product. It involves applying a layer of glitter to the edges of the paper, creating a visually stunning effect when the piece is viewed from the side.

Glitter edge is commonly used for wedding cards, bible, luxury packaging materials, books and marketing materials. It adds a touch of elegance and uniqueness to printed materials, making them stand out from the rest.

Conclusion

Post-press finish options offer a wide range of possibilities to enhance and elevate the appearance of printed materials. From lamination for protection and durability to foil stamping for luxury and elegance. Each finish option provides a unique and visually appealing effect. Combining different finishes, such as embossing, debossing, or spot UV. Designers can create stunning and memorable designs that leave a lasting impression on the recipients. When considering post-press finish options, it is important to carefully choose the technique that best complements the design and purpose of the printed materials.

Ready to custom make professional look book or marketing material to stand out from the market? Contact us today, we can help you achieve professional and high quality printed result at unbeatable price.